“Even when we didn’t get any results, I never thought it was hopeless at all.” Revealing a Story Behind the New Project of KAGOME and NEC Changing World’s Tomato Cultivation!

We interviewed KAGOME and NEC ‘s new project of applying satellite data to tomato agriculture!

Did you know that KAGOME Co., Ltd., which boasts top share in tomato ketchup, tomato juice, fruit and vegetable mixed juice market in Japan, produces tomatoes for processing those products?

Since 2015, KAGOME has been collaborating with Nippon Electric Company, Limited(NEC), and working on agricultural management support service demonstrations utilizing artificial intelligence (IT) in Portugal, Australia, United States, and many other regions.

What is the relationship between tomato farming and NEC? Sorabatake chief editor Nakamura interviewed the leading person in both companies about the project’s background and its demonstration result.

▼Mr. Kengo Nakata/ KAGOME Co., Ltd. Smart Agri Division General Manager.

Joined KAGOME Co., Ltd. in 1993. Engaged in agricultural research and development at first, and got in charge of strategic partnership with companies overseas in the Business Development Department. Living in Europe for ten years. Now working as both KAGOME Agri-Business R&D center LTDA and Smart Agri Division General Manager. Currently living in Portugal.

▼Mr. Hiro Tsutsumikawa/ KAGOME Co., Ltd. Smart Agri Division (Seconded from NEC since 2020)

Worked on marketing and business incubation for overseas business as NEC staff. Seconded to NEC Europe for five years in 2011. Started up agricultural business as a new business development specialist of global origin “Solutions for Society”. Began to take part in KAGOME since April 2020, and engaged in strategy planning, structure organizing, and customer success as business manager.

▼Ms. Norika Oki/ NEC Corporate Business Development Department

Joined NEC in 2008. Engaged in new business development for various social issues. Her first theme was planning and development of new business using robots in the field of aging education. Joined the Agriculture ICT project as a business design member since 2015. Working on expanding “CropScope” to Europe, United States, and Australia.

(1)Initiatives and Challenges of KAGOME’s Tomato Production

KAGOME Is Producing Tomato Both in Japan and Overseas

Nakamura:First of all, please let me ask about KAGOME’s tomato cultivation.

Mr. Nakata:In Japan, we mainly make tomatoes for tomato juice products. We have farmers produce tomatoes based on contract cultivation, and we purchase it, and process it to make into products.

We purchase tomatoes from foreign countries for tomato ketchup, tomato sauce, and soup. We have some bases abroad; for example, we carry out contract cultivation with HIT, KAGOME’s subsidiary, as a base in Portugal.

Nakamura:So, HIT makes contracts with Portugal’s farmers, and each farmer does the tomato cultivation.

Mr. Nakata:That’s right. There is a department called agronomists, and they give guidance for procurement. We take good communications with farmers, and supervise to prevent unexpected pesticides from being used.

Difficulty of Tomato Cultivation

Nakamura:Are there any points that you have to be careful in cultivating tomatoes?

Mr. Nakata:Cultivation of tomatoes is said to be rather difficult.

They are easily diseased, and easily damaged by pests. Also, tomatoes are weak to rain and humidity. To add more, selection and preparation of soil, preparation of healthy seedlings (for tomatoes are mostly planted from seedlings), and appropriate amount and quality of fertilizer based on the growth of tomatoes is needed. Tomato cultivation is difficult to manage.

What makes it more difficult is that the cultivating environment changes everyday, because tomatoes are cultivated outdoors in foreign countries. It rains, wind blows, it gets cloudy, it gets cold, it gets hot; and we need to manage by using water, fertilizers, or sometimes pesticides, according to the circumstances.

These management were originally controlled by each farmer’s experience and intuition, therefore, there were gaps between farmers. For this reason, making it easier for anyone to manage the crops appropriately by utilizing IT was one of the things I wanted to do.

Agricultural Management Guidance and Issues

Nakamura:Please tell us more about how you manage each farmer’s cultivation situation.

Mr. Tsutsumikawa:Like processing companies such as KAGOME, there are some patterns in purchasing tomatoes from farmers. There are mainly two patterns; one is to give some agricultural management guidance to the farmer, and the other is to leave it all to farmers.

However, management is up to farmers, so most of the farmers selected their way of cultivating with their experience and intuition. By this, the amount of procurement depends on the skills of each farmer, and tomato processing companies result in carrying the problem of unstable procurement

To solve this problem, we give agricultural management guidance using manpower, but this approach is also problematic, for limited members of farming leaders must take care of vast numbers of fields in the case of fields abroad.

To give an example, the size of the largest tomato field which the contract farmer in Portugal owns is about 600 hectare (same as 120 Tokyo Domes!).

Even if there were three members who can give agricultural management guidance, there are about 60 contract farmers, which leaves a staff quota to give guidance to 20 farmers in a week. 20 farmers means there are lots more fields; it is impossible to manage.

The Goal Was to Achieve “Low Input/High Output” Farming

Mr. Tsutsumikawa:To solve this problem, our solution was to reduce management costs of farming guidance and to activate communication with farmers, utilizing IT technologies such as AI and satellite data.

These are some examples of solutions we offer: Make AI learn the tacit knowledge used in production sites and convert it to explicit knowledge so that anyone can achieve a certain level of result, or, centralize and share the information of the fields so that farmers can make decisions faster.

Mr. Nakata:What KAGOME wanted to do was to realize “Low Input/High Output”.

There is a problem both in Japan and the world that farmers give too much water or fertilizers (=High Input) to achieve a lot of yield, and results in using extra resources. This agriculture, to take a long view, is not sustainable to the environment.。

We want to realize stable agriculture in the medium- to long-term, by increasing agricultural efficiency with minimum effort (whether it is “Low Input” or Optimum Input”).

(2) Meeting with NEC and First Challenge Together

Sounds Interesting, Let’s Do It Then!

Nakamura:Will you tell us about the background of the project from the very beginning?

Mr. Tsutsumikawa:The business division was established in 2020, but it took five years to reach its establishment.

I met Mr. Nakata in 2015 in Europe, and “the timing and what we wanted to do complimented each other’s goal perfectly”.

As for KAGOME, they wanted to establish a research center (Agri Center) in Portugal (for its Mediterranean climate suitable for tomato farming) and improve the cultivation itself. To add more, KAGOME wanted to expand the “KAGOME Method” to the world.

As for NEC, we wanted to expand global business by utilizing IT’s advantage of “power of expanding to a wide area”, and I was in charge of starting up a business in the agricultural field.

Like this, our vision matched perfectly, and we said “it sounds interesting, let’s do it then!”. And the project started rapidly.

First Approach Didn’t Go As Expected

Nakamura:How did you start the project?

Mr. Tsutsumikawa:We decided to take steps and verify it, and we started by verifying the core technology which NEC possesses as a service.

In the first year, we gathered datas and grasped the local trends. Next year, we utilized the technology which just came up from the research center (the technology just a step before becoming a prototype) and did a small trial. We verified how the farming recommendation function works with local farmers who were interested.

The result was, to be frank, it didn’t work out as we expected.

Our “Technology” was this; apply collected data to a cloud analytics platform, then create a crop model, perform a growth simulation, and give the best farming advice.

We hadn’t implemented machine learning back then; We thought (typical textbook-like) growth simulation is good enough for making good crops. In other words, we thought if we could gather many datas, we could find a farming method that surpasses humans. However, it didn’t work out as we expected, and this was the result of our first challenge.

(3) Meeting with Professional Farmer, Leading to Commercialization

Inspired by the Encounter with a Tomato Farming Professional

Nakamura:I see full-scale use of the system began after several years. What led to the success?

Mr. Tsutsumikawa:Besides our unsuccessful circumstance in 2016, there was a farmer who recorded yield over 145 tons, where average yield in Portugal was about 90 ton per hectare. That was a farmer who had professional farming skills, and was respected by all local farmers.

Mr. Nakata:He was a professional, engaged in tomato farming for about 40 years. When I set up a research center in Portugal, I happened to meet him, and deepened engagement.

Mr. Tsutsumikawa:Comparing his result and ours, we decided to change the technological approach. As for our second approach, we accumulated information focusing on the professional’s farming data, installed machine learning, and adopted the professional’s farming method into AI.

Adopting the Professional’s Farming Method into AI

Nakamura:I heard it was only two seasons in “accumulating the professional’s farming data” and “machine learning”. It was great that you got good datas and was able to actually put it to practical use.

Mr. Tsutsumikawa:We got to take live data, but what helped us greatly was that we had an honor to get offered past records.

What was most important was, as verifying together, we were provided with questions such as ”What difference is there besides you and this AI?” or ”What do you focus on when you make a decision on farming?” from KAGOME’s research center. This led to the efficient advance of machine learning.

Nakamura:What kind of data did you get in particular?

Mr. Tsutsumikawa:We call it “farming policy”; first, we grasped the timing of when to give more/less water during one season.

In the growing simulation of the crops, we put stress on the crop and calculate the amount of water and fertilizer required. To grow crops well, it isn’t always right to grow crops under an environment with absolutely no stress. There is know-how such as, reducing the amount of water at the timing a little before harvest season to increase Brix of the fruits, or, reducing the amount of water at the beginning of the season to help the plants grow its roots better.

We asked about these “farming policies” one by one.

It needed a deep interview; we shared our farming patterns and asked “how do you think?”, and we showed our farming and received indications everyday.

Sometimes, we asked the professional to let us install his farming pattern to our model and made graphs, and our research team asked “why did you reduce/increase the amount of water here? Please tell us”. It was a series of steady work like that.

As data accumulated, performance came out to a certain extent and technical prospects came out in 2019. In the meantime, we considered its commercialization, and here we are now.

“Sustainable Farming” Grabbed the Professional’s Heart

Nakamura:I think help from the farming expertise is absolutely essential in these mechanization. On the other hand, I hear sometimes it doesn’t go well because increasing use of artificial intelligence brings a sense of crisis to them. Why do you think that professional farmers were so cooperative this time? What do you think was the motivation?

Mr. Nakata:I think he helped us because he really liked to make good tomatoes and also he liked new things such as these technologies. Maybe there was a sense of contribution that he wanted to generously initiate his techniques to all farmers.

Ms. Oki:I think it was also because he sympathized with KAGOME’s concept of “Low Input/High Output”. He understood well that it leads to sustainable farming. I feel that he was motivated by that, and agreed to the idea of realizing it using IT and AI.

Nakamura:How was his reaction when he actually saw the technology such as satellite data and AI?

Ms. Oki:He checks the field using his own feet, so it might be that he didn’t get surprised because the sense he had and the satellite data matched. It was like “Hmm, that field seemed successful in the satellite data, and it is actually growing well,” or “That field seemed bad, and it isn’t growing well”, so he might have thought it useful.

Mr. Tsutsumikawa:There was once a conversation like this; when we were discussing about the result of AI analysis, we said “yield of the field was great this time, but it might have been much better if we have reconsidered the farming at the time,” he said “Yes, I thought so too”!

Skeptical Public Changed Their View

Mr. Tsutsumikawa:To be frank, most of the members involved in the project (both the company staff and the farmers) were doubtful at the timing of 2015, except Mr. Nakata.

I feel that farmers, typically speaking, are not always welcome toward these technologies. Maybe there underlies ideas that they may lose their jobs, or it’s doubtful, or “We can’t believe what IT companies do because when it doesn’t go well as they thought it would, then they will suddenly abandon us”. Past five or six years that we developed a relationship with farmers in Portugal has been a positive factor in gaining trust from all members that were involved in the project.

Mr. Nakata:The sense of speed of business development is very different in IT business. I am thankful NEC worked with patience, because it led us here.

Mr. Tsutsumikawa:It’s true that we worked with patience, but I think we owe it to Mr. Nakata, for he believed in its success and created the opportunity to proceed the project. I think it was a combination of such attitudes.

Mr. Nakata:Even when I didn’t get any results, I never thought it was hopeless at all. The concept “Conversion of Tacit Knowledge to Explicit Knowledge” was an absolute value. I can easily imagine that it can come true if we add devices and refinements. In fact, this field is getting competitive around the world. I knew that we were doing the right thing, so the stance for working as joint development never changed from the beginning.

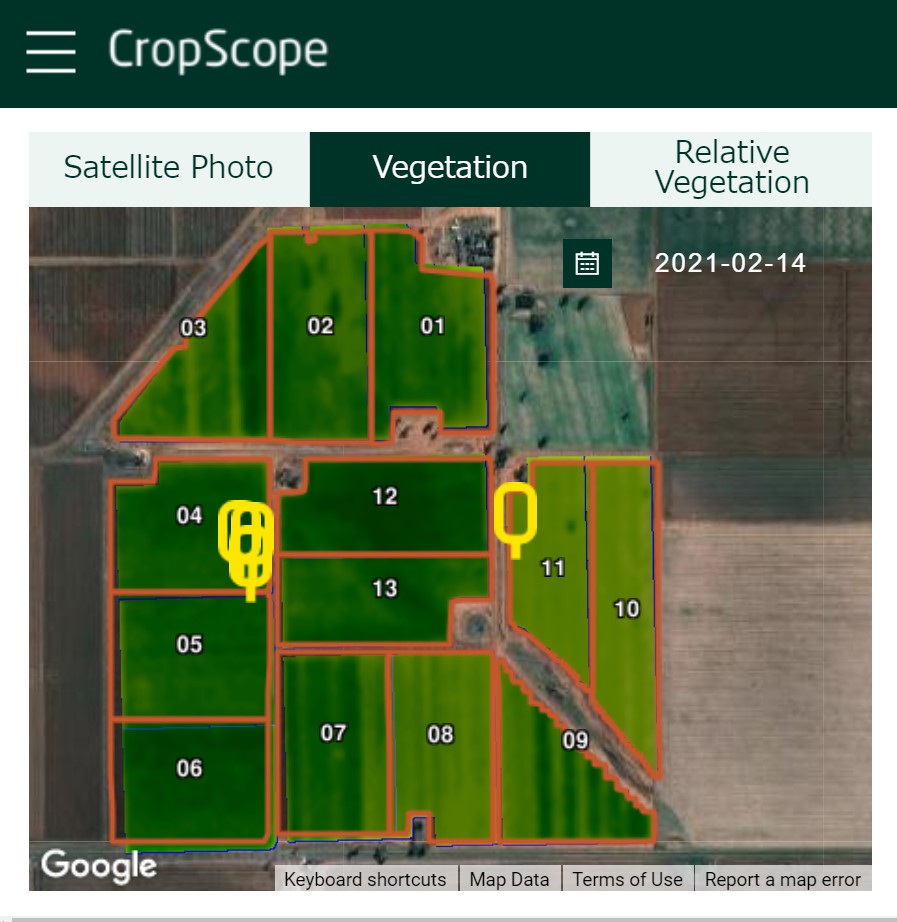

Credit : CropScope

Nakamura:Was there a point you noticed that the skeptical public changed their view?

Mr. Nakata:I think change occurred after we got the outcome from verification of some improvements we made based on works of 2018 and 2019. The timing that NEC officially released partial service and was in a positive attitude also acted as a big help. Management staff of KAGOME said “This seems to work!” or “We can have high hopes for that!”, and it was decided to work together as a business in 2019.

(4) What Have Actually Changed from The Technology in Use

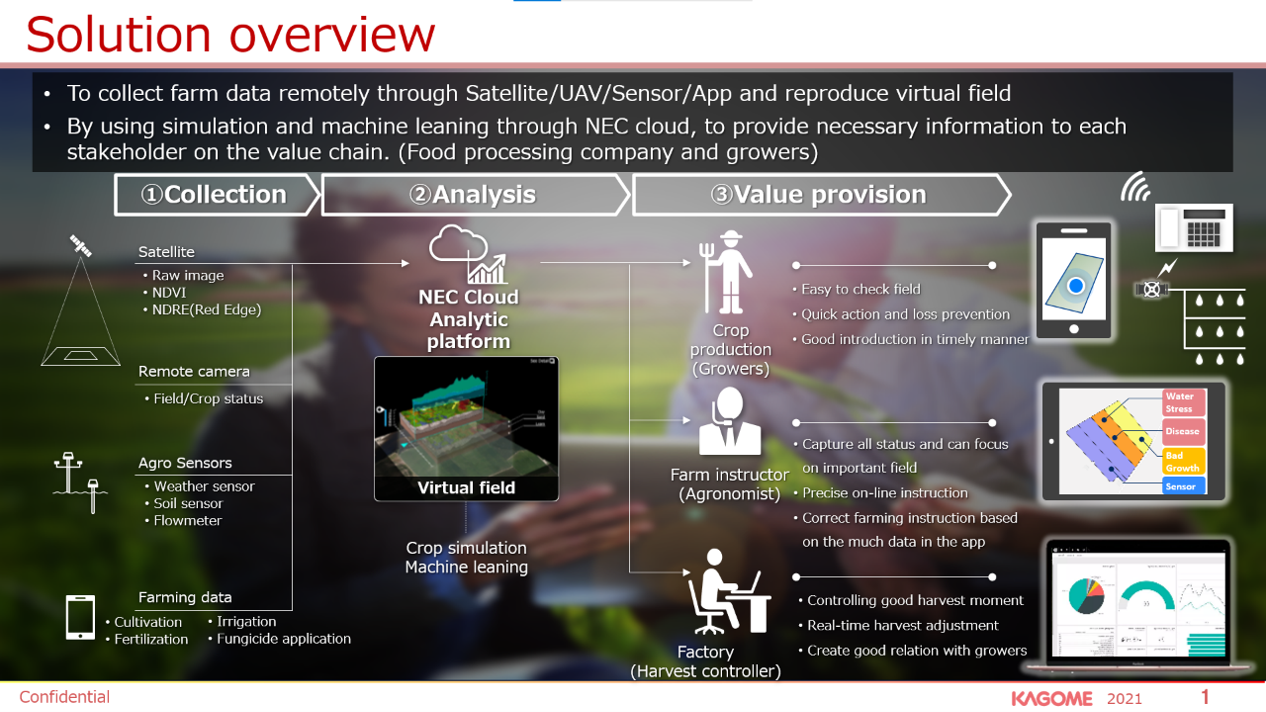

Agricultural ICT Platform ”CropScope” Solution Overview

Nakamura:Now, I want to ask about “CropScope”, the released agricultural ICT platform. What kind of technology is being used?

Mr. Tsutsumikawa:Data used are Satellite data, remote cameras, agricultural sensors, and farming datas. NEC is developing an application for collecting farming data, and it is for mobile applications and web applications. As for agricultural sensors, it consists of soil sensors and weather sensors.

The product name is called “CropScope”, and its concept is to influence and enhance each other by centralizing information on the cloud and sharing it with everyone.

Releasing the farming field management function as a basic service, we are thinking of adding disease management function as an option service, and eventually we would like to release AI farming advice function too.

Method called “drip-irrigation” is often used in the tomato fields abroad. In this method, frequent control is possible because liquid fertilizer is mixed in the irrigation tube.

The amount and the timing of this fertilization gives great effect to the final yield, so we would like to make an AI estimate automatically and adjust the amount of liquid fertilizer in the tube, and realize automatic farming in open fields in the future.

Nakamura:If this becomes true, it means there will be time that there is no need for farmers to go out to the fields by themselves! That is fantastic!

Advantages of Using Satellite Data

Nakamura:Have you considered using drones instead of satellite datas?

Mr. Tsutsumikawa:Yes, in fact, we had been using drones. However, it costs too much to fly multiple flights when put into practical use as a service. To add more, the resolution of satellite data was increasing, so we decided to use satellite data as a main source.

Nakamura:Which satellite data are you currently using, specifically?

Ms. Oki:We are using the free Sentinel-2 satellite data, from Europe’s satellite.

Nakamura:I see that the resolution level of Sentinel-2 is ten meters. Is it enough as data?

Mr. Tsutsumikawa: Yes, it is okay with large fields overseas. However, we are currently working on a trial operation in Japan, but it is rather difficult for the domestic farming fields because it seems rough. Also, there is a problem that we can’t get good data during rainy seasons.

Ms. Oki:The good points of satellites are that we can get a one-shot picture of a vast site that is completely different from that of Japan for free, and as for Sentinel-2, the picture is taken every five days, so it meets the required frequency and size.

There are customers who say that they want to check more frequently than every five days. However, there are large advantages, because the growth can be checked every five days during tomatoes’ growing period (which is about 120 days), and it can be checked from the sky (no need for walking through the vast fields!).

What Was Acquired from the Solution

Nakamura:Was there anything that farmers acquired by using “CropScope”?

Ms. Oki:I think there was a time advantage, because they are able to collect information for amount of water, fertilizer, and pesticides without having to walk through the fields. It means they can focus on other necessary things.

Mr. Tsutsumikawa:Producers’ aim is very simple: it is “Low Input/ High Output” that I introduced earlier. Therefore, it goes simply like, “I will do other things if AI is taking care of water and fertilizers”. I think they will spend time pursuing better farming, which is an endless journey.

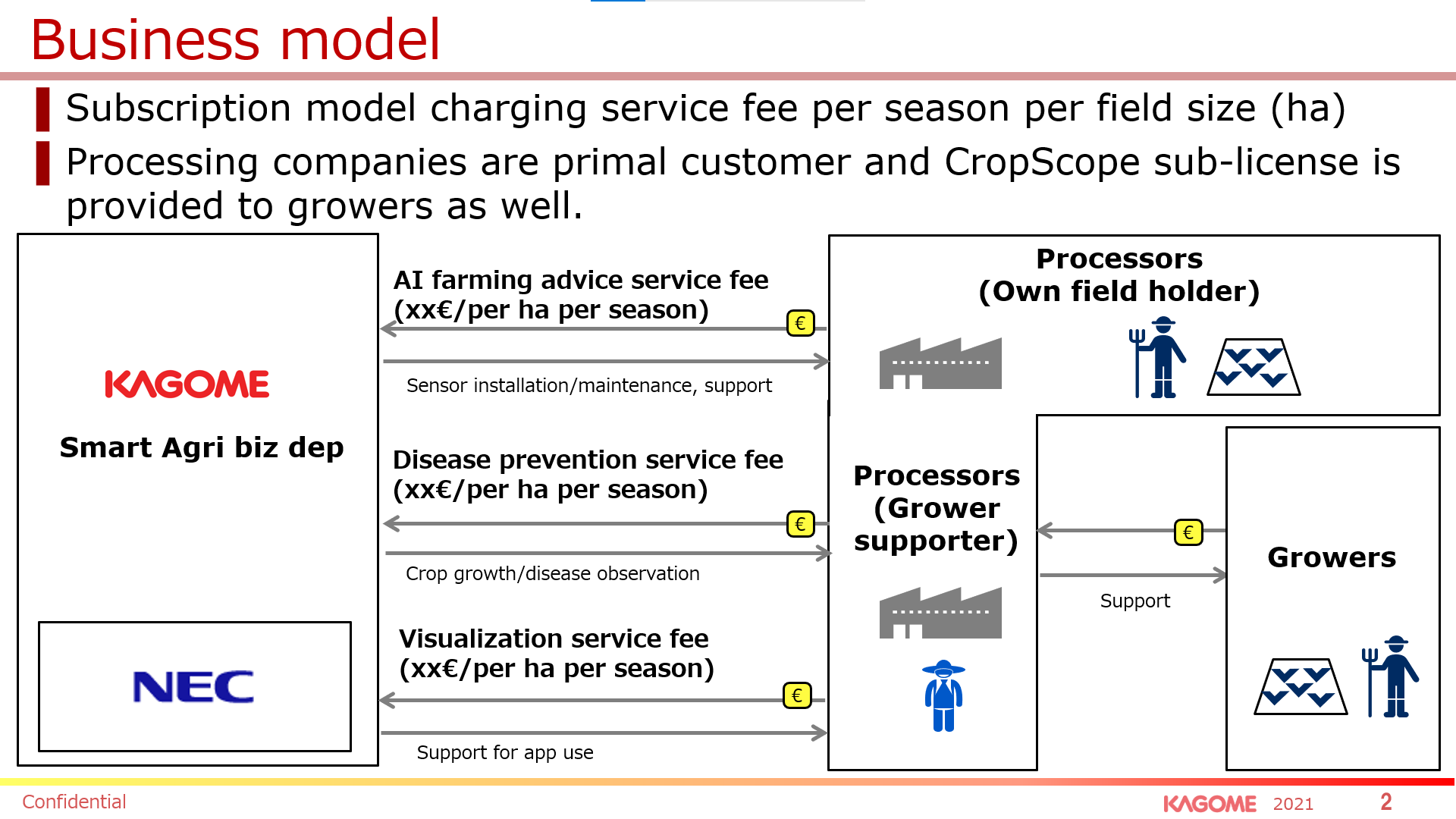

(5) Business Model and Its Differentiation

Subscription Model With Processing Company As Customers

Nakamura:May I ask about the business? Would you tell me about the business model?

Mr. Tsutsumikawa:To talk about the business model, we are targeting tomato processing companies. The service can be used by subscription, and the service fee will be charged for each hectares per season. The basic service charges for hectares, and disease risk prediction and AI farming advising service can be added to this.

There are two reasons why we set processing companies as targets; One is because it will take too much person-hours if we make each farmer a customer, and another reason is that KAGOME is well known in the processed tomato industry, and NEC is good at B to B business.

In addition to it, the concept of the service is to “influence and enhance each other by centralizing information on the cloud and sharing it with everyone”, so the effect of this synergy may be difficult to see unless it is a large-scale farm. To corral the affiliate farmers of processing companies, I think the effect of the service is much easier to be sensed.

Nakamura:Please tell us about the current introduction situation of the solution.

Mr. Tsutsumikawa:Visualization service has become popular in the past six years. This service has been used in a cumulative total of 11,000 hectares since 2015, and in fiscal year 2021, 5,500 hectares are already contracted for a single year.

Last year was 6,000 hectares, and the year before was 3,000 hectares. Rate has been very good, and the full-scale operation is on the brink of realization. We are very happy with this outcome.

The Point of the Differentiation Is AI Farming Consulting

Nakamura:What are the differentiation points with services of other companies?

Mr. Tsutsumikawa:Simply quantifying satellite datas and visualizing growth information is too common as a service, so it is rather difficult to make a difference.

Therefore, we think it is important to provide a service that handles the complicated parts all combined, such as dealing with crop disease and farming control. Our strategy is to get into the field as soon as possible and win market share, and build entry barriers.

Nakamura:As I heard you mention about the automatic farming by AI before, what is the differentiation on this point?

Mr. Tsutsumikawa:We think it is necessary to strengthen AI in a short period of time in addition to accumulating more datas. I think how much we can step into and strengthen AI is the point, for in addition to learning from datas, we are also stepping into insights (=knowledge) of farmers who are engaged in professional farmer’s farming and taking interviews about the points of making farming decisions from them.

(6) Future Outlook

Trial in Countries Where Increase in Demand for Tomato Pastes Are Expected

Nakamura:Lastly, I will ask you about future prospects. Which countries are expected to increase its demand for tomato pastes in the future as the population increases?

Mr. Nakata:We think Africa, for example, will become a major consumption base as the population grows. Particularly, people in West Africa eat tomato pastes frequently as traditional. However, they cannot make it themselves, so they import the cheap tomato pastes and dilute it before eating.

Assuming that there is potential for consumption, and the population is expected to grow, and the economy is expected to improve, We think it will become a large consumption base in the future.

Therefore, KAGOME is currently starting a small scale processing tomato business in Senegal.

Nakamura:I hope the tomato cultivation in Senegal will work out better in a short period of time than before, utilizing the help of the model built in the business in Portugal and the power of IT!

Expecting Utilization for Japanese Outdoor Cultivation

Nakamura:As the commercialization of ”CropScope” is progressing, are there any voices for future suggestions in KAGOME?

Mr. Nakata:Since I hear from the people saying “If it succeeded overseas, let’s try it in Japan, too!” I think the time is ripe. In particular, we focus on CropScope visualization service from 2020 through 2021. In 2021, we will increase the scale and number of places more than the year before.

Mr. Tsutsumikawa:Speaking of change that occurred in KAGOME, I feel the company’s positive attitude toward expanding the field of smartagri with the CropScope business in its base.

(7) In Conclusion

“CropScope”, a service produced from joint development of KAGOME and NEC; Behind the steady development of the service, there were determined attitude of Mr. Nakata (KAGOME) and Mr. Tsutsumikawa’s (NEC) not giving up the ideals.

Moreover there were efforts of making constant visits to the fields and picking up voices of the professional with know-how.

Maybe the business spoken with terms such as “Big data” and “AI” seems gorgeous, but the steady effort of collecting datas and verification and the strong will of the staff is essential for realizing commercialization.

We are looking forward to the world where “CropScope” will achieve further development and complete AI farming becomes a reality!