“Digital Twin technology: Definition, Differences from Simulation, Challenges Addressed, Examples from Companies, Countries, and Cities, and Notable Data”

Recently, you may have been hearing about "Digital Twins" in various places. In this article, we will give an introduction to what Digital Twins are, how they differ from simulations, the challenges they address, examples from companies, countries, and cities, and highlight some noteworthy data. Stay tuned to learn how Digital Twins are influencing your business and daily life!

In recent years, you may have heard something about “Digital Twins” from various places. Many of you might not have a full understanding of what it actually is and how it could impact your business and daily life.

In this article, we will explain the basics and features of Digital Twins, including how they differ from simulations. We will delve into the industrial and social challenges that Digital Twins address. Furthermore, we will introduce the necessary technologies and companies that are actively involved in the field of Digital Twins. Through this, you should gain a clearer understanding of how Digital Twins relate to our businesses and daily lives.

(1) What is a Digital Twin, and how does it differ from simulations?

The definition of Digital Twin:

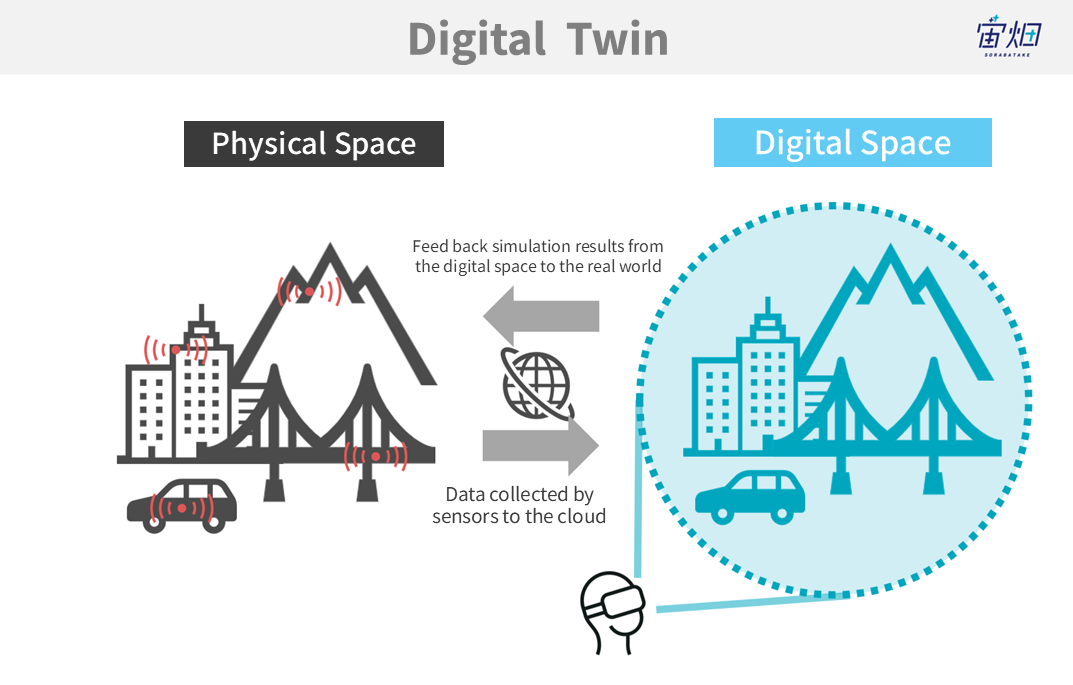

The term “Digital Twin” is written as “デジタル空間上の双子” in Japanese, which translates to “a twin in the digital space.” More specifically, it refers to the concept of collecting the state of objects or environments in the physical world, replicating them in the digital space, and recreating them.

Furthermore, it is also a simulation technology that predicts future events in a replicated digital space.

The term “Digital Twin” itself has been used in the engineering field for a long time, primarily as one of the simulation technologies. NASA’s Apollo program is considered to be the first to apply the concept, where the real world and its digital counterpart were paired.

(Reference)

The Digital Twin Paradigm for Future NASA and U.S. Air Force Vehicles

https://ntrs.nasa.gov/citations/20120008178

With the rapid advancement of technologies such as IoT, Digital Twins are now being applied to various industries, and you may have heard of them more frequently.

Difference Between Digital Twin and Simulation

So, what sets Digital Twins apart from simulations? Let’s summarize the distinctions.

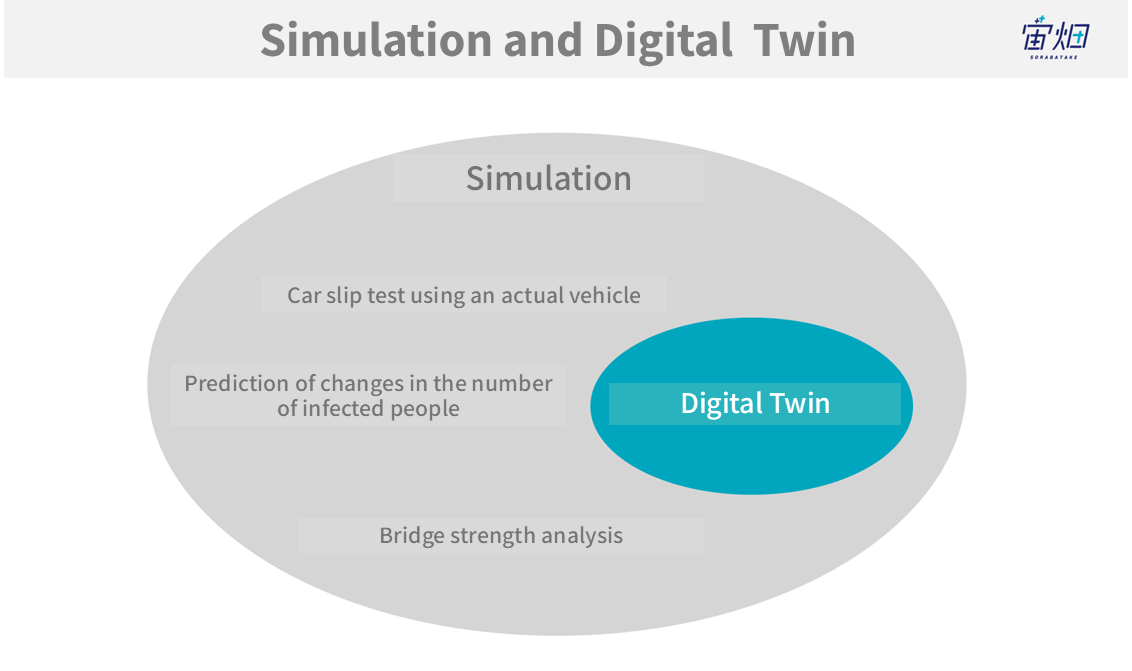

Simulation

According to a Japanese dictionary, simulation is defined as follows:

“To simulate the behavior of a physical, ecological, or social system using another system or a computer governed by nearly the same laws.”

In essence, simulation is the technology of simulating real-world occurrences in “another place,” which can include digital spaces. For instance, when simulating a car skid, an actual car might be used in a controlled environment rather than on a real road. Similarly, to experience the impact of an earthquake, there are instances where an entire room is shaken artificially.

Difference Between Digital Twin and Simulation

In other words, Digital Twins are not distinct from simulation technology; rather, they are a subset of simulation technology.

To outline the differences in approach between the general simulation methods in digital spaces and the characteristics of Digital Twins:

Interconnected with the Real World

In conventional simulations, scenarios are assumed and certain assumptions are made when initiating the analysis. In contrast, Digital Twins replicate the same environment as the real world in the digital space, eliminating the need for manual configuration. This not only reduces human effort but also enables simulations closer to reality.

High Real-Time Capability

Linked to the previous point, conventional simulations require time for analysis based on assumptions, resulting in lower real-time capability for analyzing real-world events. Conversely, Digital Twins continuously predict future events based on real-time digital information, enhancing real-time capability.

Approach to the Real World

As a result of the above, Digital Twins can predict events that will occur in the future in real-time digital spaces, establishing a connection with the real world. This capability allows for appropriate approaches to the real world, thereby avoiding potential problems that may arise.

(2) Challenges Addressed by Digital Twins: Industrial, Social, and Scientific Challenges

Industrial Challenges

Digital twins have a wide range of applications across industries. While manufacturing is a prominent example, they can be applied to industries such as energy, construction, and logistics – essentially all sectors operating in the physical world. Let’s take the manufacturing industry as an example and explore how digital twins address challenges within each phase of the value chain:

Planning and Design Phase

Reduced Prototyping Costs and Time:

Digital twins enable easy testing of multiple strategies in the digital space, leading to cost reduction and shorter prototyping periods.

Improved Product Quality and Risk Reduction: Iterative testing and simulation in the digital space help identify design and manufacturing defects that might be missed in the physical world, thus enhancing product quality.

Accurate Cost and Personnel Estimations:

Digital twins allow for precise simulation of manufacturing processes, leading to accurate estimations of costs and personnel requirements.

Estimation of necessary costs and personnel

In the design of manufacturing processes, predicting the requisite costs and human resources for novel products presents significant challenges. Digital twins technology addresses this limitation by enabling comprehensive simulation within virtual environments, thereby facilitating precise estimation of resource requirements and workforce allocation.

Production Phase

Equipment Maintenance:

Real-time monitoring of equipment conditions through digital twins accelerates issue identification, reducing downtime. Early anomaly detection can prevent failures.

Shorter Lead Times:

Real-time insights into workforce and inventory conditions enable optimization, resulting in reduced lead times and manufacturing costs.

After-Sales Service Phase

Enhanced Customer Service:

Real-time monitoring of product conditions in customers’ hands enables timely and tailored after-sales services.

Social Challenges

Digital twins not only address industry-specific challenges but can also be applied to global societal issues, including those highlighted by Sustainable Development Goals (SDGs). By offering realistic simulations of potential futures, digital twins help individuals engage with these challenges on a personal level.

Natural Disasters

For instance, NTT Communications plans to conduct evacuation training simulations in a digital space, assuming a scenario of water-related disasters in certain districts. This approach aims to engage participants and contribute to improved real-world disaster responses.

Addressing Food Shortages

In the realm of food security, IBM employs digital twins to simulate farming conditions using satellite imagery, sensor data, and weather information. This aids in predicting crop yields and optimizing agricultural practices.

CO2 Emission Reduction

Japan’s environmental policy highlights digital twins as a means to shorten development periods and reduce CO2 emissions in energy equipment.

Population and Labor Force Decline

As demonstrated earlier, digital twins can optimize labor by visualizing expertise, which is particularly valuable in a future with a diminishing skilled workforce.

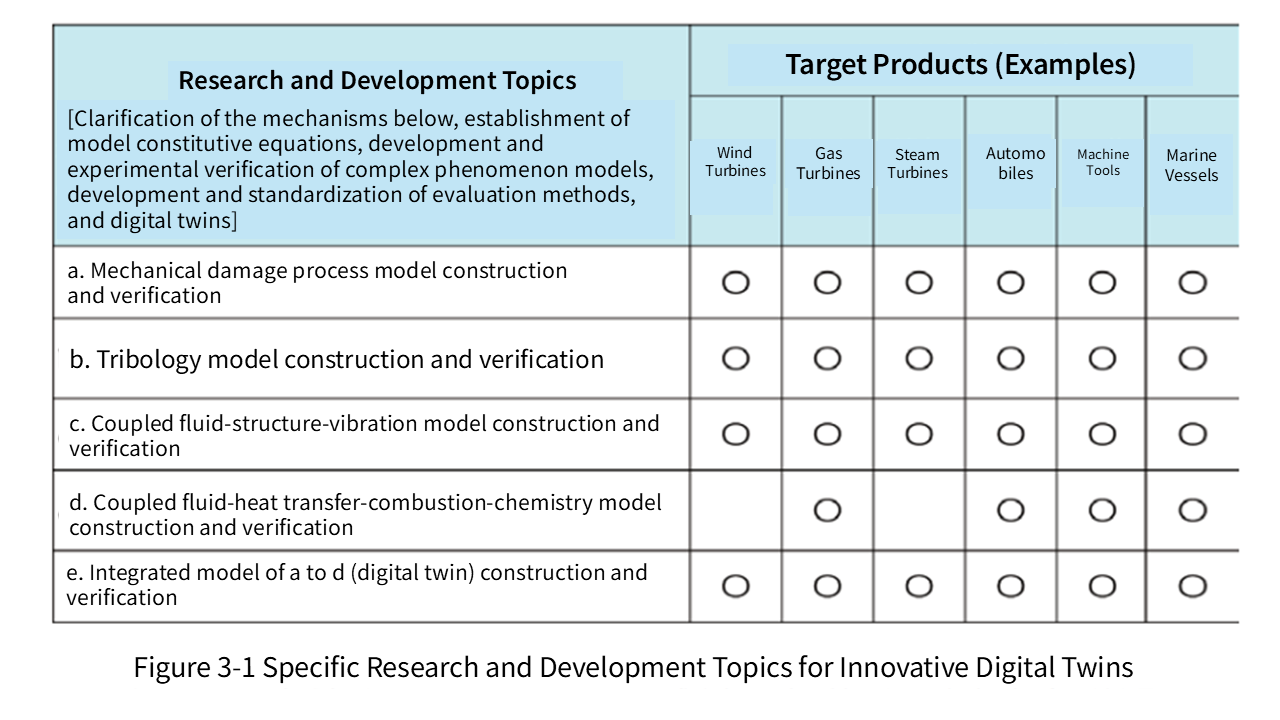

Scientific and Technological Challenges

As explained in section 1, traditional simulations rely on assumptions about physical phenomena made by humans, which can fall short in replicating complex real-world events. Digital twins offer an avenue to address these unexplained phenomena.

The Japan Science and Technology Agency’s Center for Research and Development Strategy (CRDS) has outlined research and development topics that could benefit from digital twins’ enhanced understanding.

Examining the listed topics reveals that digital twins can address issues involving fatigue in materials, where theoretical approaches alone may lack accuracy, as well as complex models involving multiple interrelated phenomena.

(3) The DX Boom Boosting Digital Twins

In recent years, within the context of the growing trend of Digital Transformation (DX), digital twins have become a significant keyword.

What is DX (Digital Transformation)?

In the document “DX Promotion Indicators” and its guidance, established by the Ministry of Economy, Trade and Industry in July of 2019, the definition of DX is described as follows:

Definition of "DX" in the "DX Promotion Indicators":

"Companies respond to rapid changes in the business environment, utilize data and digital technology to transform products, services, and business models based on customer and societal needs, and transform operations, organizations, processes, corporate culture, and climate to establish competitive advantages."

While the document primarily discusses businesses and companies, in practice, it extends more broadly to cover our entire lives, including countries and local governments, becoming enriched through data and digital technology.

Relationship Between DX and Digital Twins

As explained earlier, “digital twin” is a term that has been used for some time, but it has garnered renewed attention in the 2000s due to advancements in technology, especially within the ongoing digitalization (DX) of various entities.

As real-world situations are digitized through technologies such as IoT sensors and combined into the cloud, efforts are being made to construct “digital twins” as a means of utilizing this data and feeding back simulation results from the digital space to the real world.

“Digital twins” have gained significant attention as a specific means to achieve “DX.”

(4) How Are Digital Twins Created? Introduction to Utilized Technologies

Up until now, we have explained the benefits of digital twins. In this section, we will explain the technologies necessary to realize digital twins.

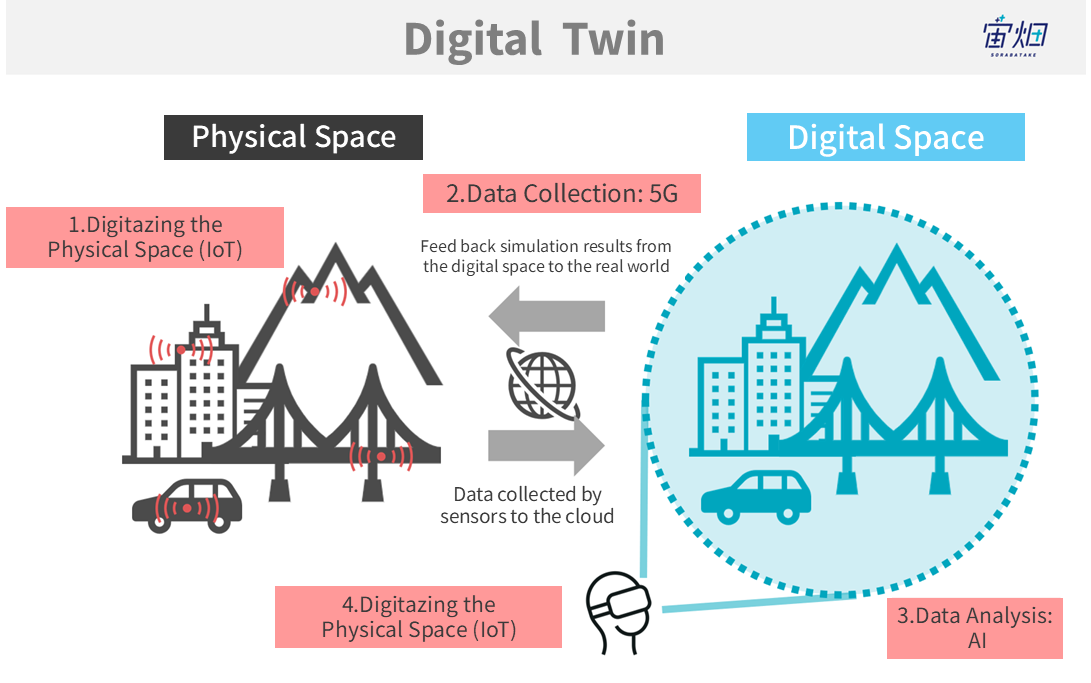

The process can be divided into four parts based on the flow of data:

1.Digitizing the Physical Space

2.Data Collection

3.Data Analysis

4.Representation in the Digital Space

1. Digitizing the Physical Space: IoT

To incorporate real-world situations into the digital space, measurements are essential.

IoT (Internet of Things), which has gained attention in recent years, allows the collection of information from various real-world objects such as cars and home appliances. This information enables the creation of a virtual world that closely resembles reality.

IoT encompasses various types, including placing small sensors in specific locations, monitoring cameras, drones, and even satellite data capturing views from space.

2. Data Collection: 5G

For collection of data in the real world onto the cloud, communication methods are crucial.

As the number of IoT sensors increases, and as the data acquisition frequency and resolution (the level of detail measured) per sensor rise, the total amount of communication required for data increases significantly.

This is where 5G, the next-generation communication system, becomes essential. It enables faster, high-capacity, low-latency communication that can connect numerous devices simultaneously. Communication providers in Japan started offering 5G services from 2020.

3. Data Analysis: AI

Based on the vast amount of data gathered on the cloud regarding real-world situations, we predict the future.

While predicting the future based on the physical phenomena discovered or understood thus far by humans, many events in the real world cannot be explained solely by human understanding. Hence, the use of AI (Artificial Intelligence) involves taking a wealth of data, including data with unclear correlations, as input to predict the future more accurately.

AI can improve accuracy with a greater variety and volume of data, making the realization of IoT and 5G technologies, introduced earlier, crucial.

4. Representation in the Digital Space: AR and VR

After collecting and analyzing real-world data, representing it in a way understandable to humans is essential. (It’s also possible to directly feed back to the real world, even if humans don’t directly perceive it.)

One notable representation method is Augmented Reality (AR), which overlays digital information on the real world, and Virtual Reality (VR), which creates a virtual environment. By expressing the analyzed future in a way that humans can realistically perceive, we can truly experience digital twins, making them feel just like the real world.

(5) Examples of Digital Twins Initiatives

Companies Engaging in Digital Twins

Siemens (Manufacturing Industry)

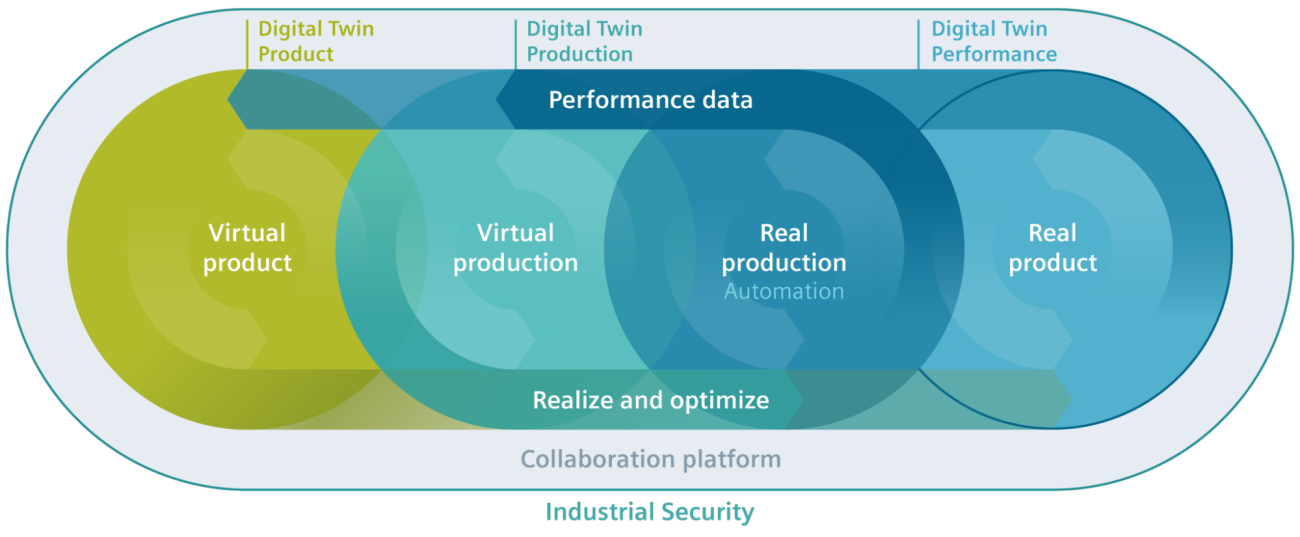

Siemens, a globally renowned technology company from Germany with roots in manufacturing that expanded into electronics, automation, and the digital domain, stands as a representative enterprise driving digital twins in the manufacturing sector.

The company has adopted “Comprehensive Digital Twin” as one of its strategies to enhance its competitive edge. Siemens’ digital twin encompasses three forms: “Product Digital Twin,” “Manufacturing Digital Twin,” and “Digital Twin Performance.”

Product Digital Twin:

For instance, when considering battery design, potential issues or faults can be identified and corrected in the digital realm before actual battery manufacturing takes place.

Manufacturing Digital Twin:

This goes beyond products to include virtual analysis of the manufacturing process, enabling optimization.

Digital Twin Performance:

As the manufacturing process progresses, data is generated abundantly in the digital twin, facilitating further improvements.

Additionally, Siemens predicts the lifespan of gearboxes in wind turbines used for wind power generation based on data such as temperature and rotation speed, thus reducing downtime. The company has also achieved over a 30% cost reduction in the development of cooling structural components for HP’s 3D printers.

Reference:

SIEMENS

https://new.siemens.com/jp/ja/markets/battery-manufacturing.html

General Electric (GE) (Aviation Industry)

General Electric (GE), an American digital industrial company, has also embraced digital twins. For instance, in the aviation sector, GE has extended the inspection intervals of jet engines from the usual 24-36 months to up to 38 months using digital twin implementation.

Reference:

Digital Twin: analysing data to predict the future.

https://www.gereports.jp/digital-twin-technology/

NTT (Telecommunications Industry)

In Japan, NTT is working on the construction of digital twins under the concept of “IOWN” (Innovative Optical and Wireless Network). NTT’s digital twin use cases include controlling human and traffic flow using 4D information of space and time to achieve congestion and traffic jam reduction, as well as predicting and addressing large-scale natural disasters for sustainable nation and city planning.

The following are some of the key objectives of the project.

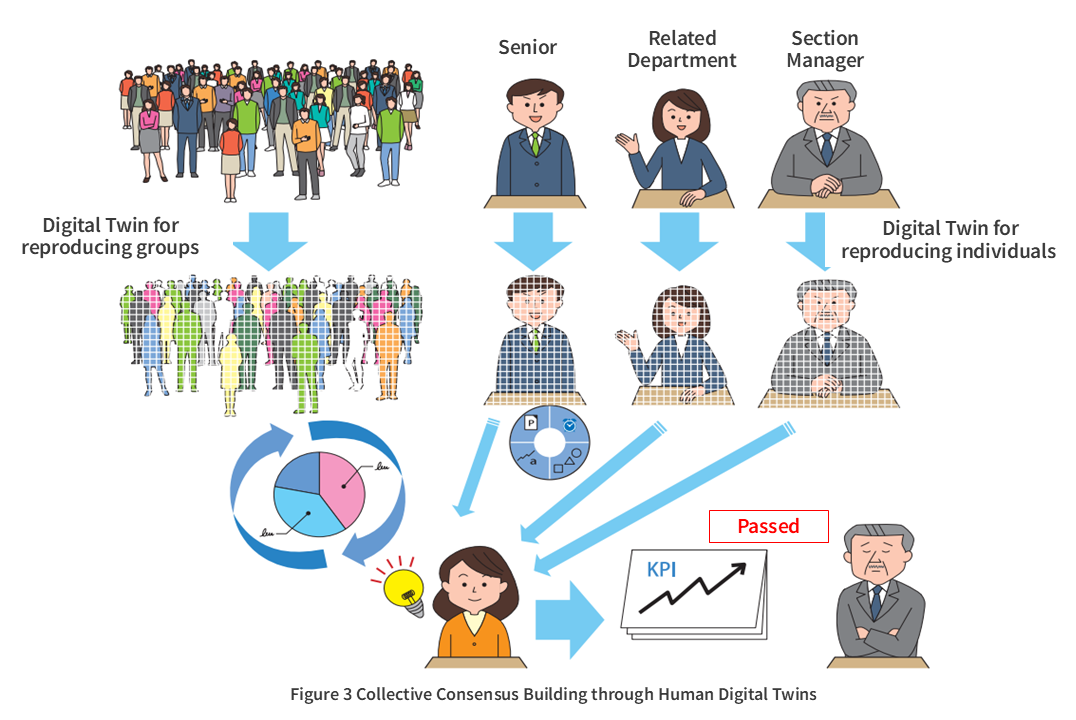

NTT is also envisioning “Human DTC (Digital Twin Computing)” to digitally capture internal aspects of humans, such as personality and thoughts, to create unprecedented value in collective decision-making.

Reference:

Special feature on the IOWN concept – Digital Twin Computing

https://journal.ntt.co.jp/wp-content/uploads/2020/06/07tokusyu.pdf

Komatsu (Construction Industry)

In the construction sector, digitalization is being driven by the introduction of ICT through policies like i-Construction promoted by Japan’s Ministry of Land, Infrastructure, Transport and Tourism. Komatsu, a construction and mining machinery manufacturer, has realized digital twins of construction sites within its “Smart Construction” service. This implementation has significantly improved surveying efficiency at construction sites, reducing a previous 4-day task to just 20 minutes.

Reference:

Part 1: The Digital Twin Revolution and the operations of Japanese companies in the post-Corona era.

https://www.nri.com/jp/knowledge/publication/cc/chitekishisan/lst/2020/09/09

Philips (Healthcare Industry)

Philips, an electrical equipment manufacturer focusing on healthcare products and medical devices, envisions using digital twins in healthcare to analyze and leverage patient data, virtually reproducing patients in real-time on digital platforms for preventive and early medical intervention.

Reference:

Philips accelerates health tech based on cross-industry collaboration.

https://xtech.nikkei.com/dm/atcl/feature/15/327441/121000598/?P=2

RealView Imaging (Healthcare Industry)

RealView Imaging, an Israeli company, uses holograms to recreate internal patient data, allowing medical professionals to manipulate and analyze this information.

Reference:

REAL VIEWING

http://realviewimaging.com/

CHESSCON (Logistics Industry)

Akquinet, a company specializing in port logistics, applies digital twins to port logistics to adjust supply-demand balances, manage inventory, and verify transportation routes.

FIELDVIEW (Agricultural Industry)

Source : https://climate.com/features/field-health-imagery

Climate uses satellite data to digitize farms, providing information on optimal actions for maximizing production.

Reference:

Part 1: The Digital Twin Revolution and the operations of Japanese companies in the post-Corona era.

https://www.nri.com/jp/knowledge/publication/cc/chitekishisan/lst/2020/09/09

Countries and Cities Engaging in Digital Twins

Not only companies are engaging into the Digital Twin. Countries and cities are also working on Digital Twin projects. Here are some of the leading countries and cities:

Singapore

Singapore began its “Smart Nation” initiative in 2014, integrating real-time data of terrain, buildings, transportation, water levels, and human positions into a 3D model named “Virtual Singapore.” This virtual model optimizes infrastructure development plans and simulates flow changes in people and vehicles to alleviate congestion and enhance construction efficiency.

Reference:

What is a smart city? 11 case studies from Japan and abroad, including Toyota, and related technologies explained in an easy-to-understand manner.

https://sorabatake.jp/18567/

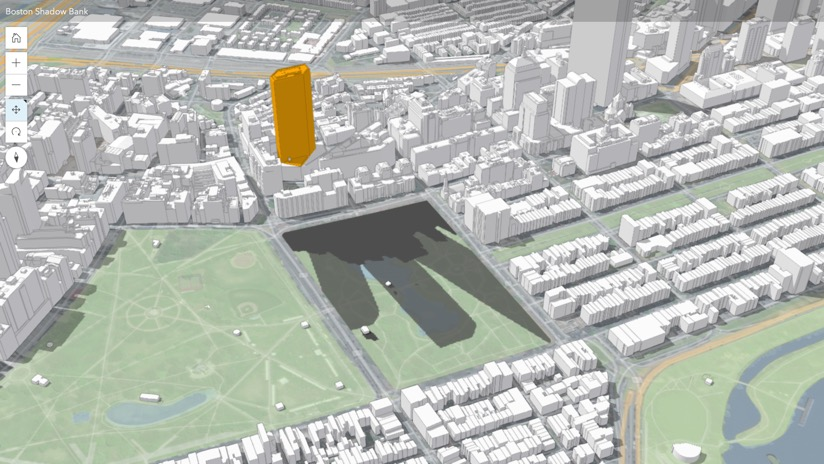

Boston, USA

Boston has been digitally simulating its city since the 1980s, initially with wooden models.

Today, digital replicas include more detailed features like water and trees. Simulations revealed that the height of new buildings could be lowered by over 24 meters without overshadowing the city’s oldest park.

Reference:

Boston Shadow Bank

https://www.arcgis.com/home/webscene/viewer.html?webscene=0589b97cb4e7481d892381fd0d2c8a21

Meet Boston’s Digital Twin

https://www.esri.com/about/newsroom/blog/3d-gis-boston-digital-twin/

Helsinki, Finland

Helsinki aims to accelerate smart city development by creating open-data city models for citizens and businesses. The model is used for analyzing solar power usage, assessing flood risks, and performing noise calculations.

Reference:

Helsinki 3D+

https://www.hel.fi/helsinki/en/administration/information/general/3d/view/view-the-models

Helsinki 3D+

https://www.bentley.com/ja/project-profiles/city-of-helsinki_helsinki-3d

Tokyo, Japan

Tokyo is also advancing various initiatives toward realizing “Smart Tokyo,” leveraging the power of digital to unlock the potential of the city. In the fiscal year 2020, the city released videos showcasing the visualization of foundational 3D digital maps (depicting urban congestion and office density) and simulations of sunlight and wind conditions, contributing to the realization of Smart Tokyo.

Reference:

Digital Twin Realisation Project

https://www.digitalservice.metro.tokyo.lg.jp/society5.0/digitaltwin.html

Shizuoka, Japan

In Shizuoka, three-dimensional point cloud data of elements like roads and terrain are released as open data. Utilizing this data, they have constructed a virtual representation of the prefecture called “VIRTUAL SHIZUOKA.” This aims to address social challenges and facilitate the creation of a convenient and sustainable regional environment.

Reference:

Shizuoka Point Cloud DB

https://pointcloud.pref.shizuoka.jp

(6) The Future of Satellite Data Accelerating Digital Twins

In this chapter, we will explain the positioning of satellite data in the context of digital twins and its future, which has been featured in several examples introduced so far.

Satellite Data as an IoT Augmentation

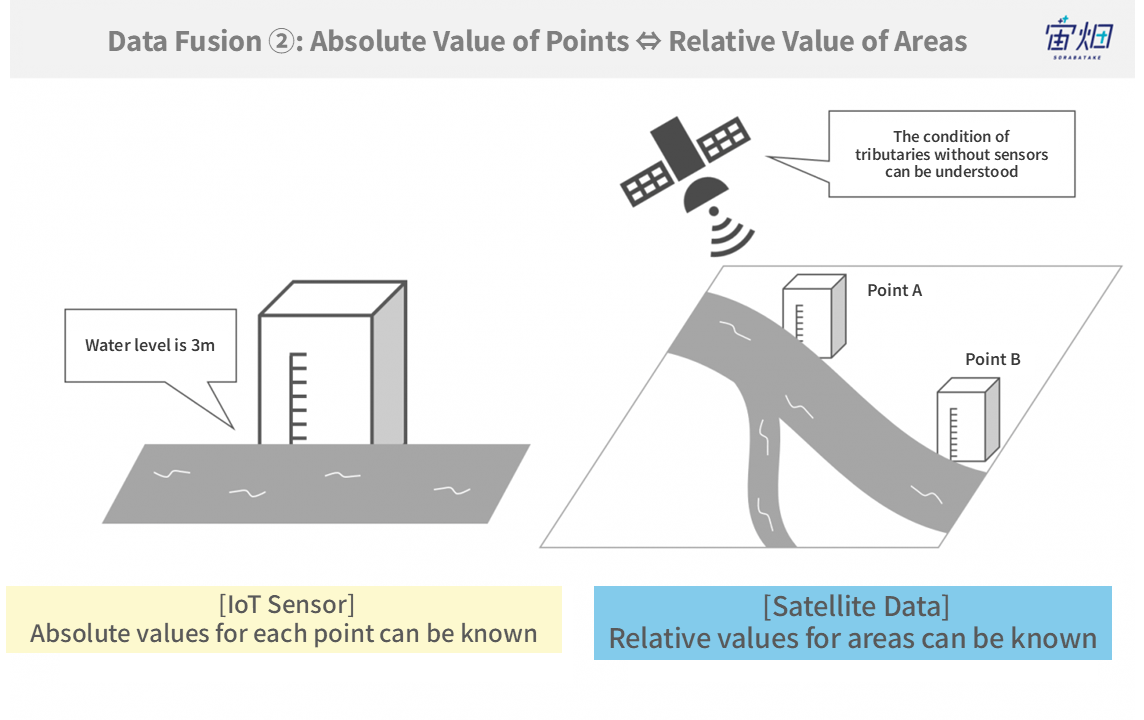

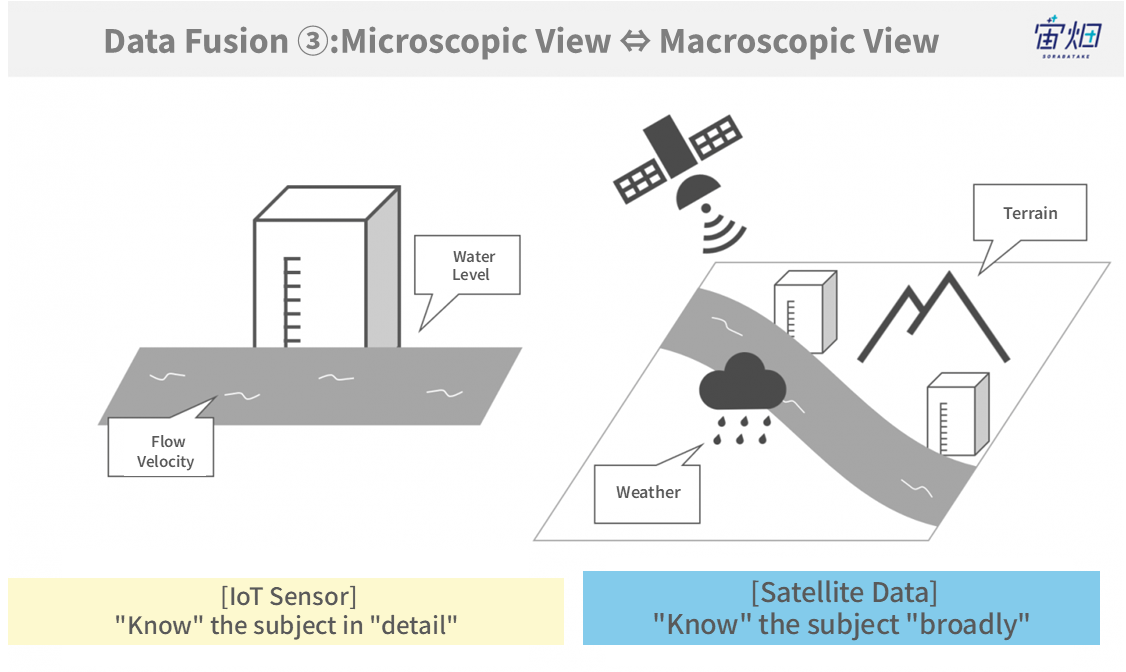

Satellite data is being recognized as a data source that complements general IoT.

Satellite data has the advantage of capturing the surrounding conditions from a spatial perspective and observing places where IoT sensors cannot be installed. This strength has also drawn attention in the context of digital twins.

For more information about IoT sensors and satellite data, please refer to the following article:

Is Satellite Data Also a Form of IoT? A Comparison and Examples with Aircraft and Drones

The Increasing Frequency and Types of Satellite Data

While satellite data is gaining attention, it is an area where numerous venture companies have entered, and investments have been pouring in. It is anticipated that the data obtained will increase exponentially in both quality and quantity.

Due to the low-cost production of artificial satellites, a large number of satellites can now be launched, resulting in a significant improvement in the frequency of capturing specific points on Earth. For example, a company like Planet in the United States is capable of capturing images of every point on Earth multiple times a day.

Furthermore, satellites that capture images using radio waves or infrared, in addition to optical images similar to smartphone cameras, have been miniaturized. With the launch of many more satellites expected in the future, the variety of data obtained is predicted to increase further. This trend will enable an even more detailed digital representation of the real Earth in the digital space.

(7) Conclusion

In this article, we introduced the theme of “Digital Twin,” discussing the issues that this technology addresses, the technological elements required for achieving Digital Twins, and showcasing countries and companies engaged in Digital Twin initiatives.

Digital Twins are a comprehensive concept closely intertwined with DX, AI, and more. In the current era where not all challenges can be resolved solely in the physical space, the concept of Digital Twins is believed to continue accelerating.

Digital twins are a broad concept applicable to nearly every industry. For the challenges faced in your own industry, why not consider what kind of data can be acquired, what analyses can be conducted, and how feedback can be provided to the physical space?